We have made it our mission to master the technological challenges of future lubricants. From this task, we have developed the USVO® technology.

Lubricant requirements for modern vehicles are growing continuously. Unwanted changes in viscosity may quickly cause serious problems. For this case, we have developed the USVO® lubricant technology with which we set a very high viscosity stability at high and low temperatures. Therefor only high-quality fully synthetic base oils and additives are used. USVO® stands for Ultra Strong Viscosity Oil.

Our USVO® qualities can be defined as follows:

THANKS TO THE IDEAL COMBINATION OF COMPONENTS, WE HAVE CREATED FORMULATIONS WITH THE FOLLOWING BENEFITS:

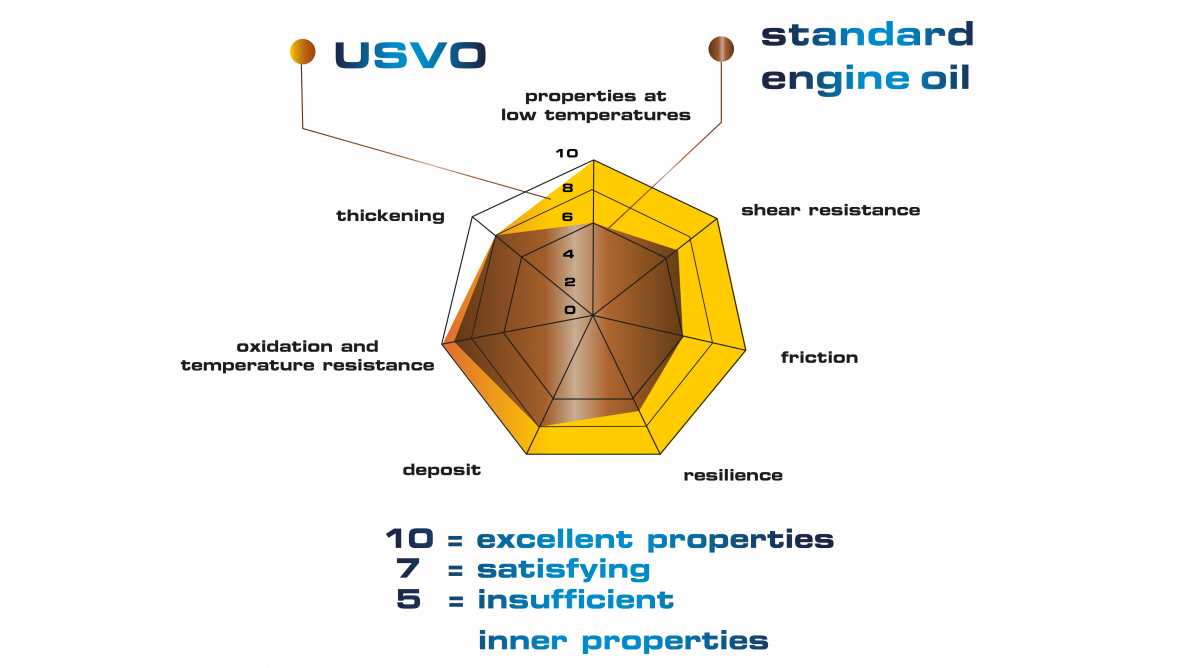

• EXCELLENT HIGH TEMPERATURE VISCOSITY (HTHS AT 150 °C)

Barely any shearing loss during operation, which means that the lubricant film is permanently maintained during operation.

• EXCELLENT PERFORMANCE AT LOW TEMPERATURES (CCS AT -30 °C)

The lubricant is always able to flow so that direct engine lubrication is guaranteed even for cold starts.

• VERY GOOD OXIDATION STABILITY

Oxidation stable lubricants have increased resistance against reacting with oxygen and temperatures. This increases the lubricant service life, which permanently prevents deposits (sludge) and maintains the lubrication properties.

• VERY LOW LOSSES DUE TO EVAPORATION

Only a few components of the oil evaporate at the high operating temperatures. As a result, the engine oil level drops only slightly and the environment is not additionally polluted by the gases.

• HIGH VISCOSITY INDEX

a high viscosity index illustrates a weak temperature-dependent viscosity change compared to a low viscosity index.

• VERY LOW POUR POINT

The pour point is the lowest temperature above which an oil is liquid. As a result, lubrication is guaranteed, even at the lowest temperatures.

The interaction of the properties ensures that a thick protective film is formed during vehicle operation, which remains stable even under high thermal and mechanical stresses.

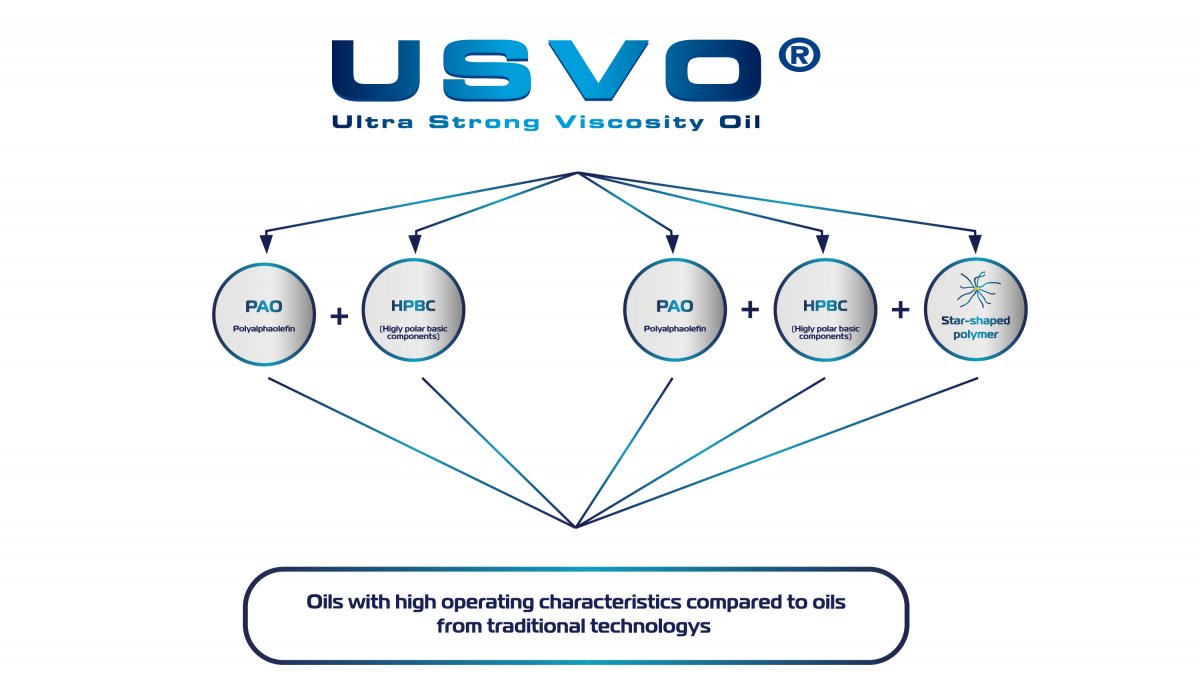

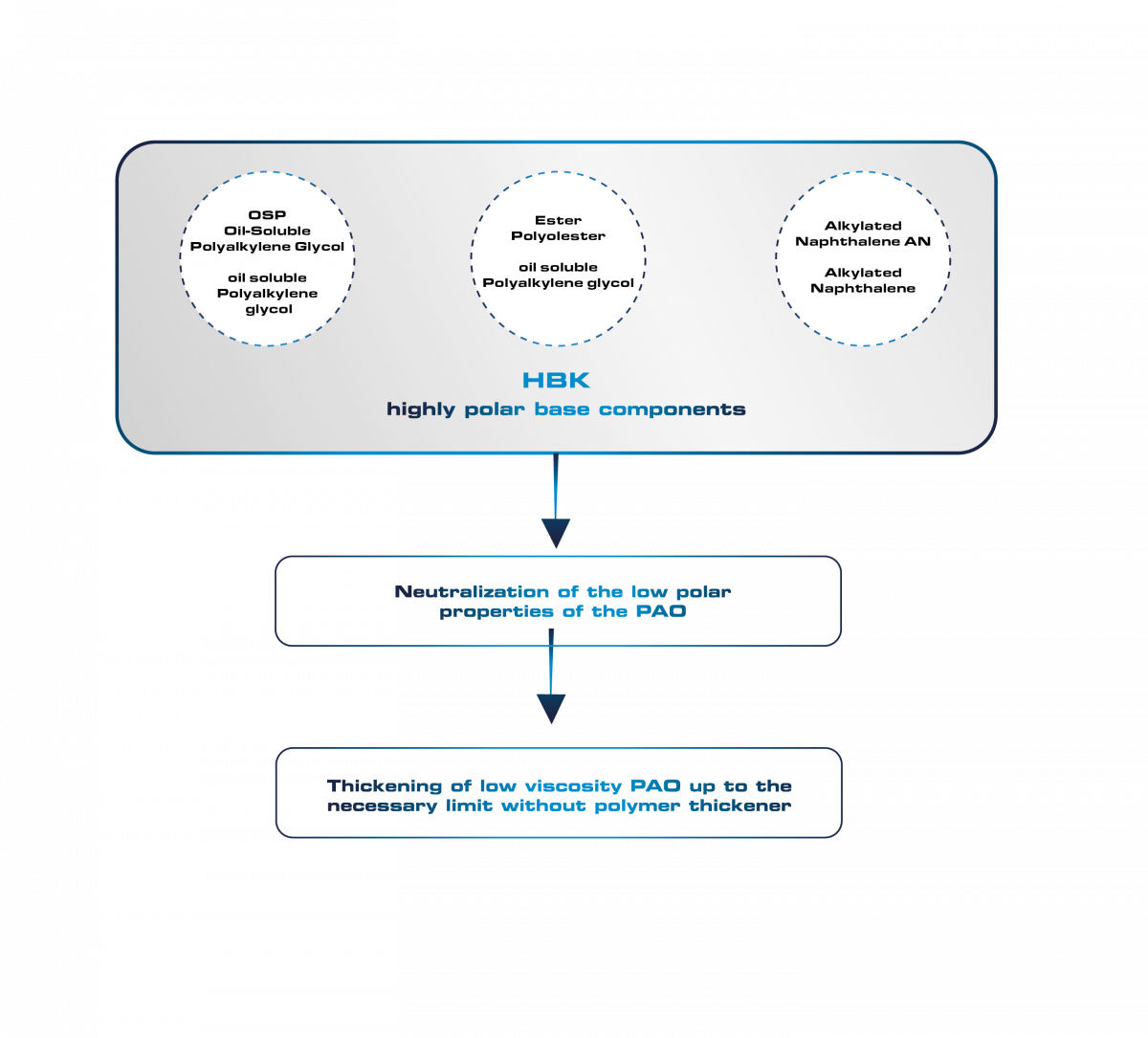

Thanks to the special combination (formulation) of the high quality fully synthetic base oils and selected special additives (without the use of polymer thickeners), an extensive process sequence can be used to manufacture outstanding oils with excellent performance thanks to their various lubrication properties.

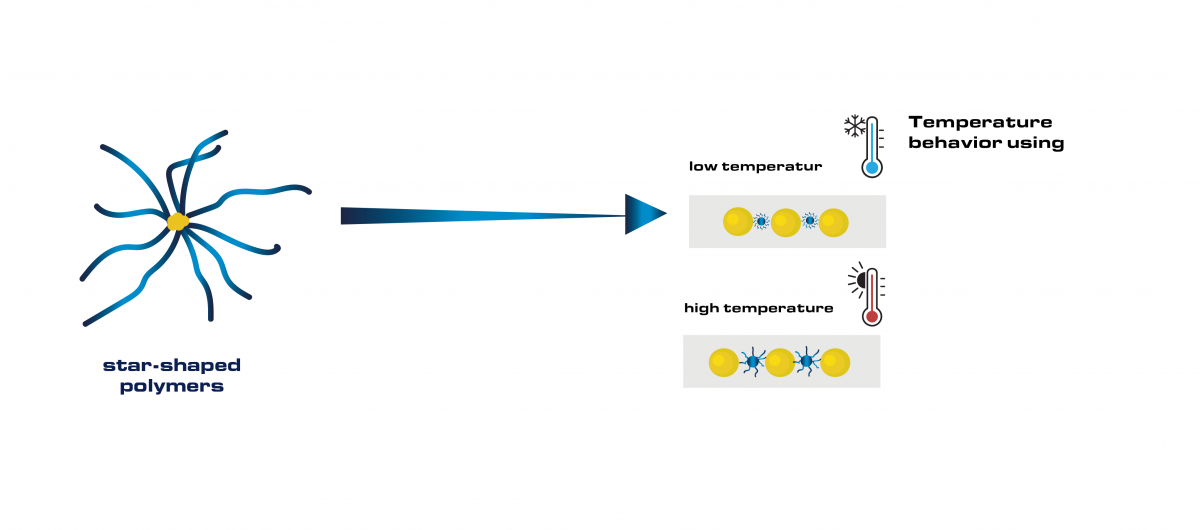

The SAE classes can not always be achieved for all viscosity grades using their base components alone. Procurement and storage are very costly and cannot always be used for economic reasons. RAVENOL therefore uses special star-shaped polymers.

The star-shaped structure of the stable molecular connections creates high shear stability. As a result, the viscosity remains stable across a broad operating spectrum. In addition, a significantly lower quantity of the star-shaped polymers is required compared to the standard OCPs (olefin copolymers).

As a general rule: The fewer polymers are present, the fewer disadvantages are caused as a result of their use.

Incorrect dosage can cause the following problems:

- increased engine soiling, which can lead to higher fuel consumption

- the formation of paint deposits and films

Thanks to their technical properties, our USVO® lubricants optimise engine performance and noticeably reduce fuel consumption at the same time. This benefits the environment, as lower fuel consumption leads to reduced CO2 emissions.

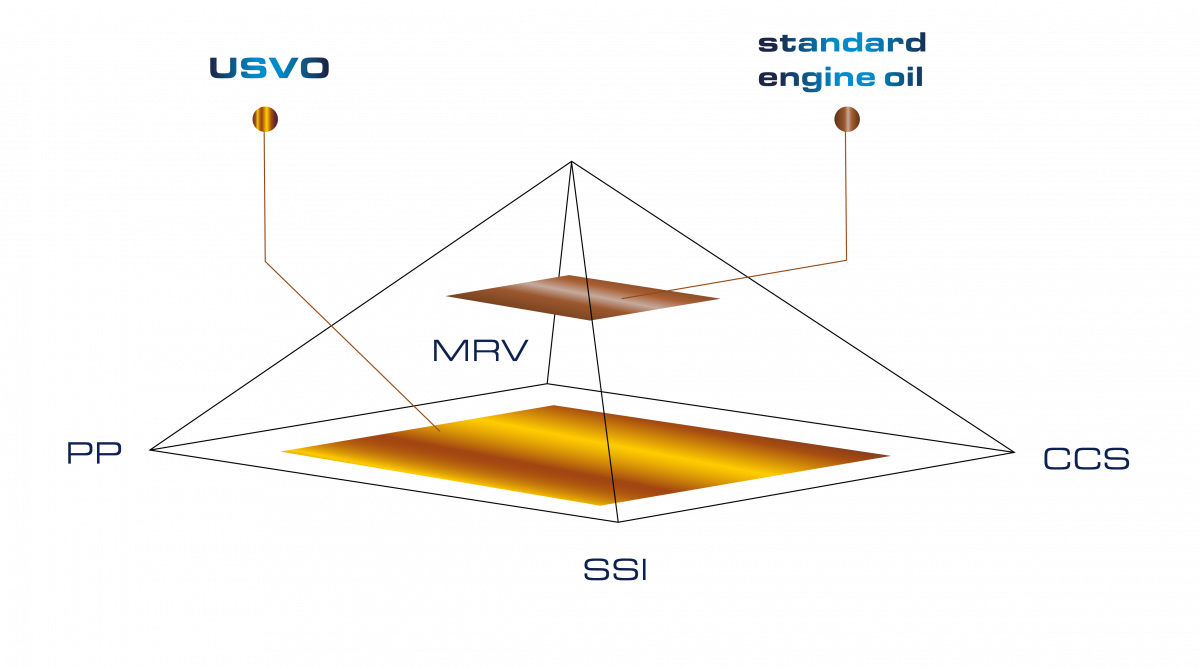

CCS = Low temperature viscosity

PP = Temperature of loss of fluidity

MRV = Low temperature viscosity when pumping through

SSI = Mechanical shear strength